Quality

At Reka, we find quality to be crucially important and that is why we invest in all process phases. Customer focus is the cornerstone of our strategy: we want to deliver the best cables to our customers fast and punctually. The well-being of the personnel and environmental responsibility lay the foundation for the company’s prosperity; sustainability and quality go hand in hand at Reka.

We put our extensive expertise into good use to manufacture the highest-quality products on the market, to develop our operating processes and to invest in production technology. The continuous improvement of our processes guarantees that our product range is evolving and expanding.

We purchase our raw materials only from suppliers that take into account the environmental impact of their own operations. In production, we minimise the amount of waste generated and sort and recycle everything we can.

We ensure the efficiency of our quality and operations management systems through internal and external auditing. We put a strong emphasis on the job orientation and training of our employees to ensure that the entire personnel is prepared to work safely and with high-quality. We want to be a respected employer, both now and in the future.

Our objective is to manage the quality aspects of our business comprehensively and systematically. Our operations manual meets the quality criteria of the ISO 9001 standard.

We develop and assess our quality constantly. Our quality management ensures the high quality of our operations, services and products.

Quality management covers quality control, quality monitoring and quality assurance. The purpose of quality control is to meet the requirements set by standards and our customers. Our quality monitoring ensures the quality of different work phases. Testing laboratories develop and assure the quality of our products.

Electrical laboratory

In the electrical laboratory, the basis of measurement is the measurement of the cable’s insulation properties. The electrical laboratory carries out the electrical conductivity and insulation measurements of conductor metals and the insulation resistance measurements of sheath materials.

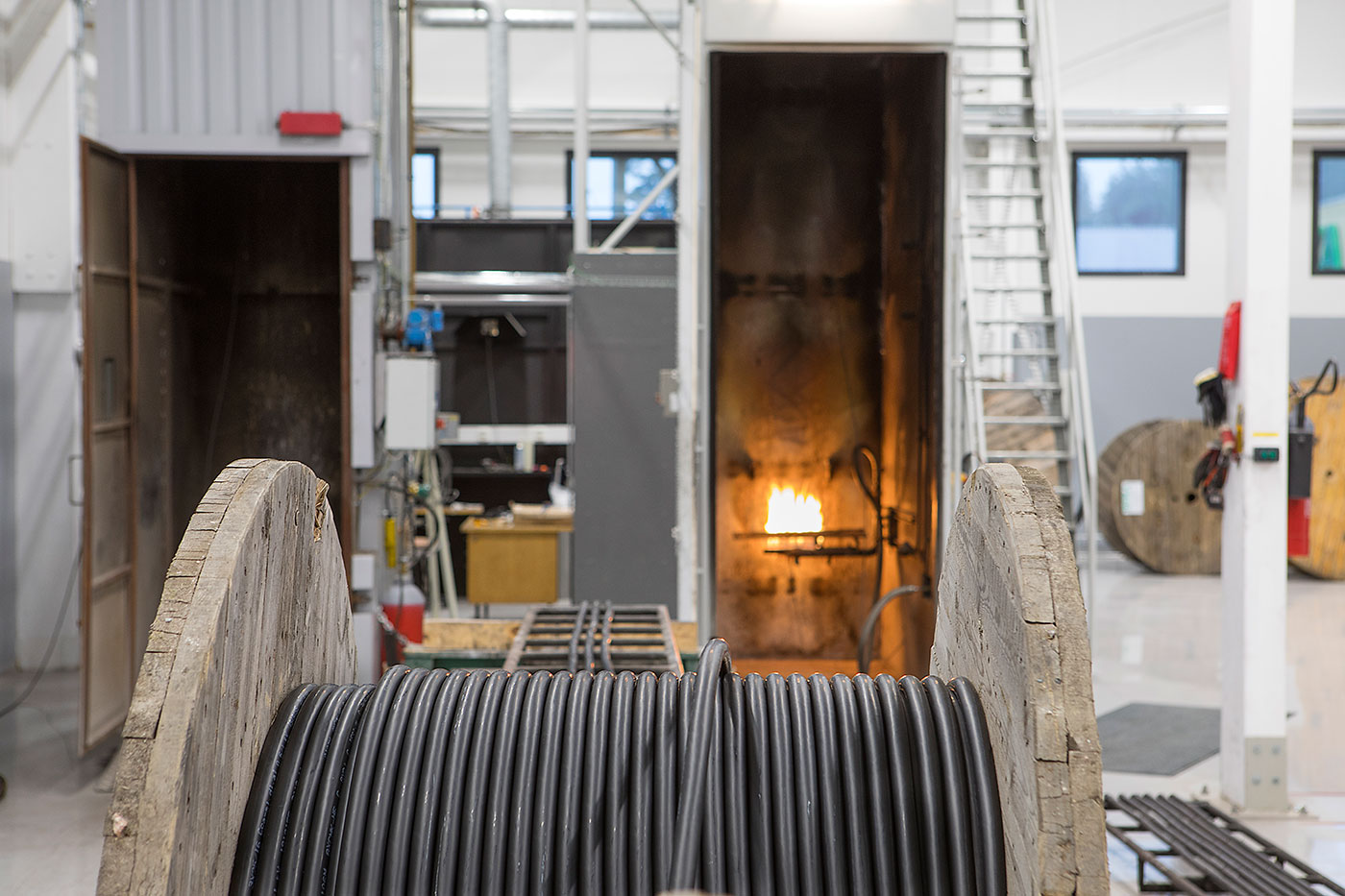

Combustion testing laboratory

In the prevention of fire damage is fire-resistant, fire-retardant cables that produce little smoke. Because a fire is always unpredictable, actual situations are simulated through a variety of tests. Our combustion testing laboratory acts as a basis for our product development and a part of production quality assurance. More information about different combustion testing methods can be found on the website of our CTC combustion testing laboratory.

Plastic laboratory

Cable products are constantly developed. Our plastic laboratory meets the challenges of the industry. Cable standards provide a basis for cable testing, in addition to which our laboratory tests the absolute limits of the durability of cable materials.

The testing laboratory experts serve all Reka Cables’ business areas with up-to-date testing methods and equipment.

High-voltage testing laboratory

Medium- and high-voltage cables are tested at the high-voltage testing room in Riihimäki.

A voltage test is carried out on the length of each drum in order to verify its insulating strength and the cable’s integrity. In monitoring the quality of insulation, a partial discharge measurement is made, which ensures that the cable’s insulation is homogeneous and that the electric field is evenly distributed.

The voltages tested in the high-voltage testing laboratory go all the way up to 230kV. In the shielded testing room, partial discharge measurements can be performed on cables with a required level of less than 2pC.